If you are someone who enjoys woodworking or metalworking, then you have probably heard of the term “radial drill press“. But what exactly is this tool and how does it differ from other types of drill presses? Whether you are a seasoned pro or just starting out in the world of drilling, understanding the capabilities and benefits of a radial drill press is important. In this blog post, we will dive into everything you need to know about this essential tool for any workshop. From its history and design to its uses and advantages, we’ll cover it all so that by the end, you’ll be equipped with all the knowledge you need to make an informed decision on whether a radial drill press is right for your project needs. So let’s get started!

What Is A Radial Drill Press?

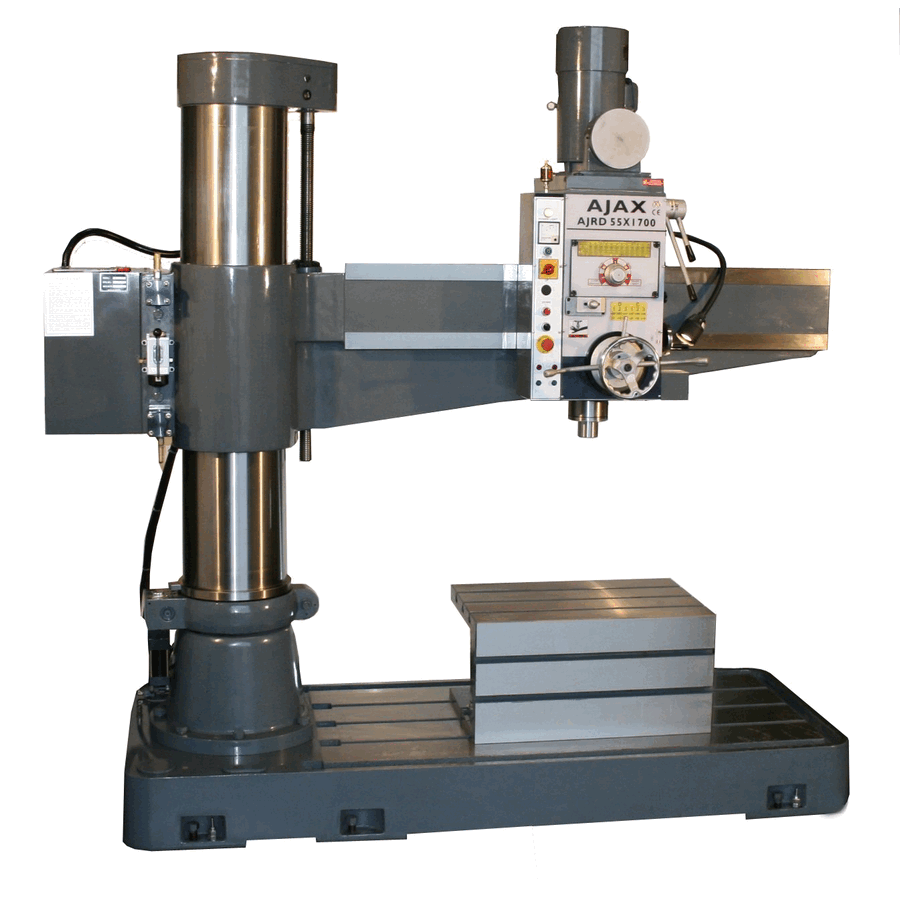

A radial drill press is a specialized type of drill press that allows the user to adjust the location of the spindle relative to the workpiece. This is achieved by a movable arm, known as the “radial arm”, which can swing around to any position within its range of motion.

The key advantage of a radial drill press is its versatility. Unlike a standard drill press, which can only drill holes vertically down into a piece of material, a radial drill press can be adjusted to drill at different angles and in different positions. This makes it an invaluable tool for jobs that require a high degree of precision or flexibility.

In addition to the movable arm, most radial drill presses also include features like adjustable speed controls, a tilting work table, and a depth stop for drilling multiple holes to the same depth. These features make the radial drill press a versatile and precise tool for a variety of drilling tasks.

Radial drill presses are commonly used in professional woodworking and metalworking shops, but they can also be found in home workshops where precision and flexibility are required.

How Does A Radial Drill Press Differ From A Traditional Drill Press?

A radial drill press differs from a traditional drill press primarily in terms of functionality and design. Unlike a traditional drill press that only moves vertically, a radial drill press offers increased versatility with its arm that can swing around to any position. This feature allows for drilling at different angles and positions on a large workpiece without the need to reposition the piece itself, thereby enhancing efficiency and precision in woodworking and metalworking applications.

What Are The Main Components Of A Radial Drill Press?

A radial drill press consists of several key components that work together to provide its functionality:

- Base: This is the bottom part of the drill press that provides stability and support to the entire machine.

- Column: The column is a vertical post that supports the radial arm and other components. It’s usually made of solid steel for rigidity.

- Radial arm: This is the movable arm that allows the spindle and drill head to be positioned over different parts of the workpiece. The radial arm can be rotated around the column and moved up and down along its length.

- Motor: The motor powers the drill press. It is usually an electric motor and it drives the spindle through a series of belts and pulleys.

- Spindle: The spindle holds the drill bit and rotates it to perform the drilling operation. The speed of the spindle can usually be adjusted by changing the configuration of the drive belts and pulleys.

- Drill head: This component holds the spindle and motor. It can be moved up and down the radial arm to adjust the distance between the drill bit and the workpiece.

- Table: The table supports the workpiece during drilling. It can often be tilted to allow for angled drilling, and some models may have a system for raising and lowering the table along the column.

- Depth stop: This is a mechanism that allows the user to set a specific depth for the drilling operation, ensuring that all holes are drilled to the same depth.

- Chuck: The chuck is the part of the drill that holds the drill bit. It can be tightened or loosened to change the drill bit.

These are the main components that you’ll find on most radial drill presses, but specific models may include additional features or variations on these components.

What Types Of Materials Can A Radial Drill Press Work With?

A radial drill press is highly versatile and can work with a wide variety of materials. It is commonly used to drill through wood and metal, thanks to its power and precision. However, it’s not limited to these. With the right drill bits, it can also penetrate materials like plastic, glass, ceramics, and even different types of stone. It’s crucial to use the correct drill bit for each material to avoid damage and ensure efficient drilling.

How Do I Properly Set Up And Adjust A Radial Drill Press?

Setting up and adjusting a radial drill press requires careful attention to ensure safe and efficient operation.

Place the drill press in an appropriate location: Aim for a well-lit, clutter-free spot with ample space for maneuvering your workpieces.

Secure the drill press: Depending on your particular model, you may need to bolt down your drill press to prevent unwanted movement during operation.

Install the drill bit: Carefully insert the drill bit into the chuck and tighten it securely. Ensure the bit is straight and correctly aligned.

Adjust the table: If your drill press has an adjustable table, position it at a height that gives you enough room to work with your material. The table should be at a safe and comfortable height for you.

Set the depth stop: If your work requires a specific drill depth, use the depth stop to set this limit.

Adjust the speed: Radial drill presses often come with variable speed settings. Choose a speed appropriate for the material you are drilling.

How Does The Arm Rotation Feature Work On A Radial Drill Press?

The arm rotation feature on a radial drill press is a defining characteristic that sets it apart from traditional drill presses. The arm is mounted on the top of the press, and it can swing around the entire machine, providing the flexibility to drill holes not just in the center, but anywhere on the work surface. This rotation is typically facilitated by a pivot point at the base of the arm. With a simple adjustment, the arm can be moved around to the desired angle and then locked in place, allowing for precision drilling at various positions on a large workpiece without the need to move the piece itself. This arm rotation feature greatly enhances the versatility and efficiency of the radial drill press, making it a valuable tool for a wide range of applications.

Can A Radial Drill Press Be Used For Other Tasks Besides Drilling?

Yes, a radial drill press can be utilized for other tasks besides drilling. With the appropriate accessories and attachments, it can be adapted to perform tasks such as sanding, grinding, or even milling. For example, by swapping out the drill bit with a sanding drum, the radial drill press can be used for sanding and polishing applications. Similarly, using a grinding wheel attachment can transform it into a surface grinder. However, it’s important to note that while these adaptations can increase the versatility of the radial drill press, they may not yield the same level of performance or precision as tools specifically designed for these tasks.

In conclusion, a radial drill press is a powerful and versatile tool that has revolutionized the world of drilling. From its unique design to its wide range of applications, a radial drill press offers precision, efficiency, and convenience for any kind of drilling task. Best Drill Press Formetal have explored its history, components, modes of operation, and even how to choose the right one for your needs. Now, it’s up to you to put this knowledge into practice.

So why wait? Whether you are a professional machinist or an enthusiastic DIYer, a radial drill press is an essential addition to your workshop. With its ability to perform various tasks such as drilling angled holes and tapping threads with ease, it will save you time and effort while providing accurate results. Don’t miss out on the benefits this amazing tool has to offer.

As the CEO of BestDrillPressforMetal.com, I take immense pride in our unwavering commitment to transformation and excellence in metalworking. I am driven and passionate about creating the best possible user experience for our customers and helping them achieve their goals with precision and innovation. With my guidance, we have established ourselves as a leader and trusted partner within the industry by leveraging cutting-edge technologies to push boundaries with incredible products that exceed expectations. We understand that metalworking is more than just a process; it is an art form made real through passion, dedication, and diligence—all of which embody our core values at BestDrillPressforMetal.com.